Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

What are the characteristics of IC test seat?

Source:

Author:

What are the characteristics of IC test seat?

IC test seat can be mainly used to check the online monolithic IC components and the circuit through the network of the open and short circuit, as well as the function of the technical simulator and digital device logic system function analysis test. The user fully realizes the functions and performance indicators specified in the design specification under harsh environmental conditions during the testing process. Simply put, it tests the chip's qualifications.

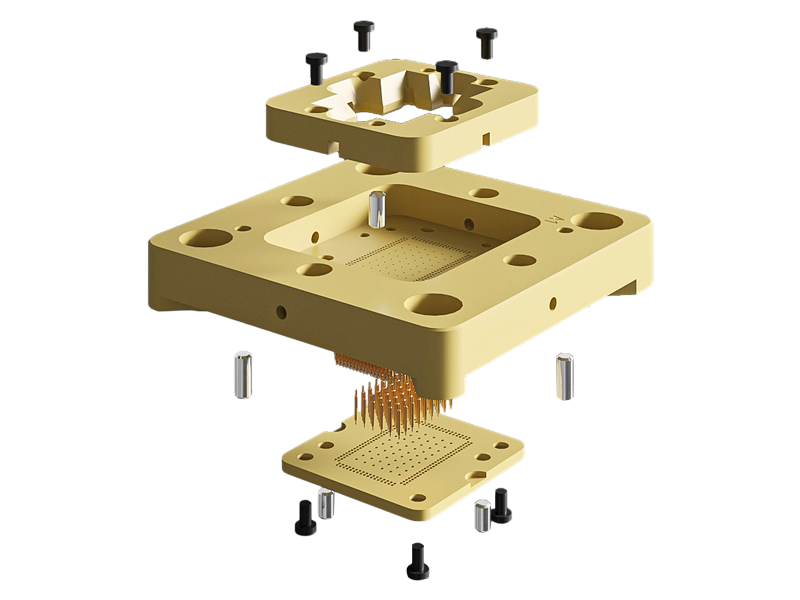

The IC test seat used for post-packaging IC test mainly includes an upper cover plate (contact plate) and a base (ic seat) assembled with each other. In the preferred implementation state, the IC test stand is used for packaging and testing ceramic lead chip carriers in image sensors (ImageSensor).

The IC test seat is characterized in that the upper cover plate (contact sheet) is provided with a through hole, a plurality of test probes are arranged near the through hole for contact with the IC to be tested, and the internal probe of each test is provided with a test spring. The test probe is arranged around the through hole.

IC test seat is used to burn the program into the chip, burning needs the cooperation of the programmer. Put the IC test socket into the socket of the programmer, and then put the IC chip into the socket for programming. So what does the IC test bench do?

The functions of the IC test seat include:

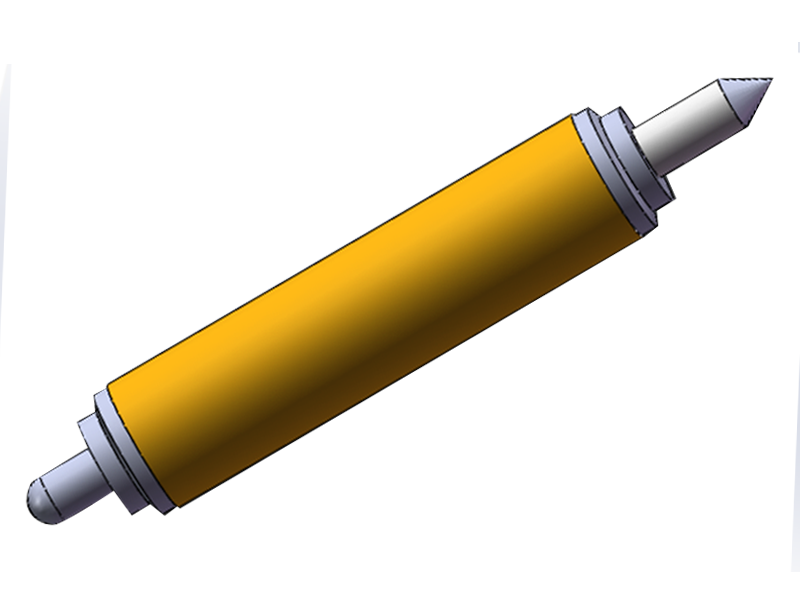

Probe balls as small as 0.3mm can be customized to the surface of existing equipment;

Double-sided test;

A variety of cover styles are available;

Ultra-thin cover suitable for microscopic detection;

A variety of different types of spring test probe to meet the needs of most students in the enterprise (lead-free, low inductance, high strength, high current, Kelvin test information socket, etc.;

Test seat:

Open the IC test seat for tempering;

Low inductance test probes for RF characterization and testing;

High strength thimble for lead-free packaging;

The IC test socket has a built-in opening for easy component placement.

The IC test socket is designed to fully achieve the functions and performance indicators specified in the design specification under harsh environmental conditions during testing. Is a standard test device used to test electrical performance and electrical connections of in-line components to check for manufacturing defects and defective components.

IC test seat adopts manual rotation structure and automatic press structure, the IC press plate on the rotating cover adopts spring press structure, which can automatically adjust the downward pressure to ensure the uniform IC press.

The special head of the probe can Pierce the oxide layer of the welding ball, reliable contact without damaging the welding ball. High precision product positioning slot or pilot hole, to ensure accurate IC positioning, high production efficiency, can be replaced by a probe, easy maintenance and management, low cost.

Lanyi Electronics - Semiconductor Test Probe Manufacturing Plant

Customer first, quality first, unity and cooperation, mutual benefit and win-win

Copyright © 2022 Dongguan Lanyi Electronic Technology Co., Ltd. All Rights Reserved. 粤ICP备17061266号 Powered by www.300.cn SEO