language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Exploring the Significance of Common PCB Spring Test Probes in Electronics Testing

Source:

Author:

In the realm of electronics manufacturing, ensuring the reliability and functionality of printed circuit boards (PCBs) is paramount. One essential component in this testing process is the common PCB spring test probe. These probes play a critical role in verifying electrical connections and signal integrity, making them indispensable tools in the production and quality assurance phases of electronic components.

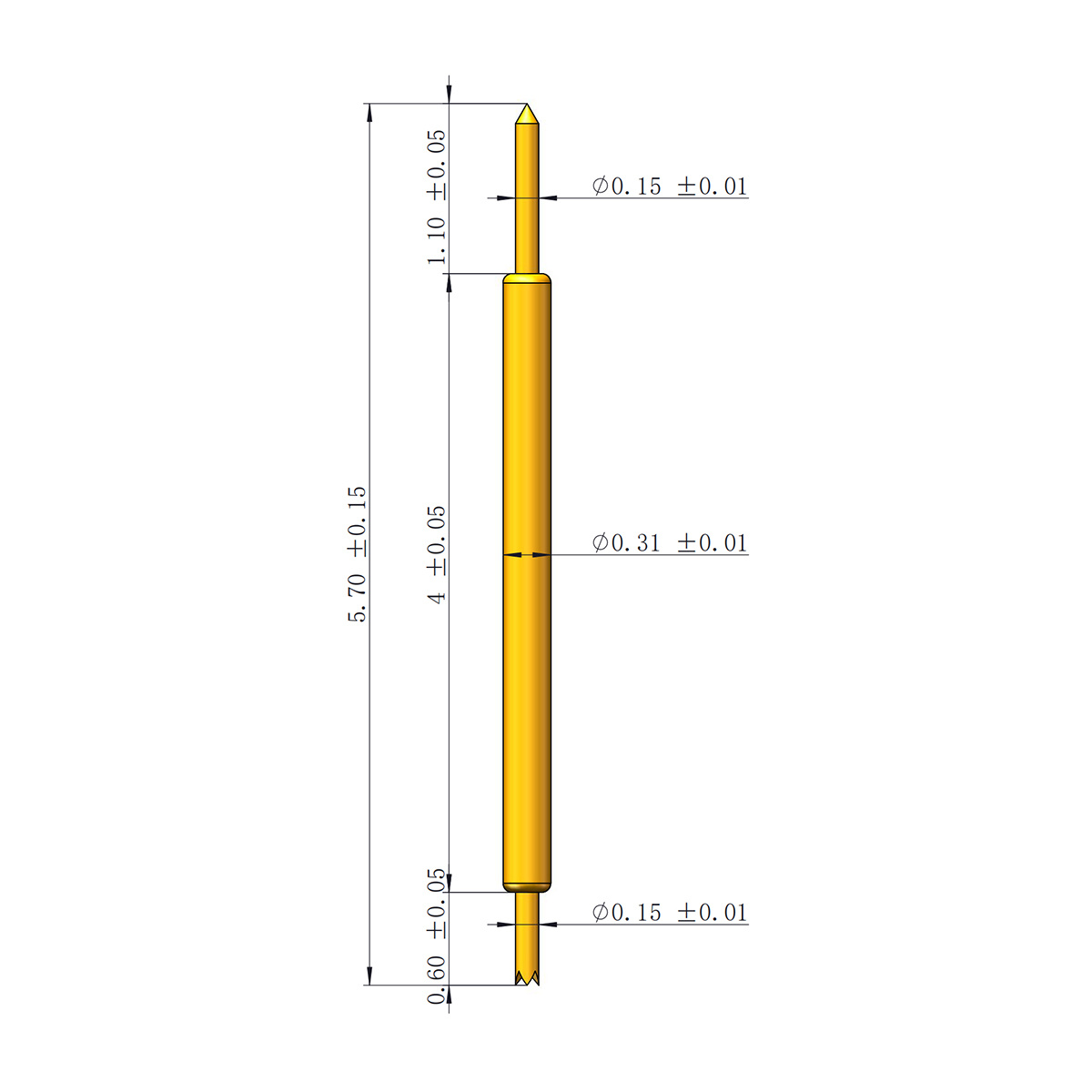

Common PCB spring test probes are designed to make temporary electrical connections with the pads on a PCB during testing. Their spring-loaded design allows for a secure yet flexible connection, accommodating variations in board height and ensuring consistent contact pressure. This feature is particularly beneficial in high-density applications where space is limited, and precision is key.

One of the primary advantages of using spring test probes is their ability to deliver accurate test results. They help in diagnosing issues such as shorts, opens, and signal integrity problems, enabling engineers to make informed decisions about design adjustments or repairs. Moreover, using these probes can significantly reduce the time required for testing, thereby increasing overall productivity in the manufacturing process.

In addition to their functionality, common PCB spring test probes are also versatile in their applications. They can be employed in various testing scenarios, including in-circuit testing (ICT), functional testing, and automated test equipment (ATE). This versatility makes them suitable for a wide range of electronic devices, from consumer electronics to complex industrial machinery.

When selecting a spring test probe, it’s essential to consider factors such as contact material, probe tip shape, and spring force. These parameters can directly influence the performance and longevity of the probe, as well as the quality of the test results. For instance, gold-plated tips may be preferred for their corrosion resistance and low contact resistance, while the spring force should be chosen based on the specific requirements of the PCB layout.

In conclusion, common PCB spring test probes are vital tools in the electronics industry, providing reliable, efficient, and accurate testing capabilities. Their unique design and versatility cater to the demanding needs of modern electronic manufacturing, making them a standard choice for professionals seeking to enhance their testing processes. By understanding the significance of these probes, engineers and technicians can better appreciate their role in ensuring the quality and reliability of electronic products.

Common PCB spring test probes are designed to make temporary electrical connections with the pads on a PCB during testing. Their spring-loaded design allows for a secure yet flexible connection, accommodating variations in board height and ensuring consistent contact pressure. This feature is particularly beneficial in high-density applications where space is limited, and precision is key.

One of the primary advantages of using spring test probes is their ability to deliver accurate test results. They help in diagnosing issues such as shorts, opens, and signal integrity problems, enabling engineers to make informed decisions about design adjustments or repairs. Moreover, using these probes can significantly reduce the time required for testing, thereby increasing overall productivity in the manufacturing process.

In addition to their functionality, common PCB spring test probes are also versatile in their applications. They can be employed in various testing scenarios, including in-circuit testing (ICT), functional testing, and automated test equipment (ATE). This versatility makes them suitable for a wide range of electronic devices, from consumer electronics to complex industrial machinery.

When selecting a spring test probe, it’s essential to consider factors such as contact material, probe tip shape, and spring force. These parameters can directly influence the performance and longevity of the probe, as well as the quality of the test results. For instance, gold-plated tips may be preferred for their corrosion resistance and low contact resistance, while the spring force should be chosen based on the specific requirements of the PCB layout.

In conclusion, common PCB spring test probes are vital tools in the electronics industry, providing reliable, efficient, and accurate testing capabilities. Their unique design and versatility cater to the demanding needs of modern electronic manufacturing, making them a standard choice for professionals seeking to enhance their testing processes. By understanding the significance of these probes, engineers and technicians can better appreciate their role in ensuring the quality and reliability of electronic products.

在线客服

Lanyi Electronics - Semiconductor Test Probe Manufacturing Plant

Customer first, quality first, unity and cooperation, mutual benefit and win-win

Copyright © 2022 Dongguan Lanyi Electronic Technology Co., Ltd. All Rights Reserved. 粤ICP备17061266号 Powered by www.300.cn SEO