Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Test probe related introduction

Source:

Author:

Test probe related introduction

The selection of the test probe, whether it can access the characteristics, and ensuring a certain degree of accuracy during the contact process are the concerns of the user. At present, there are many kinds of probes, different shapes, different materials.

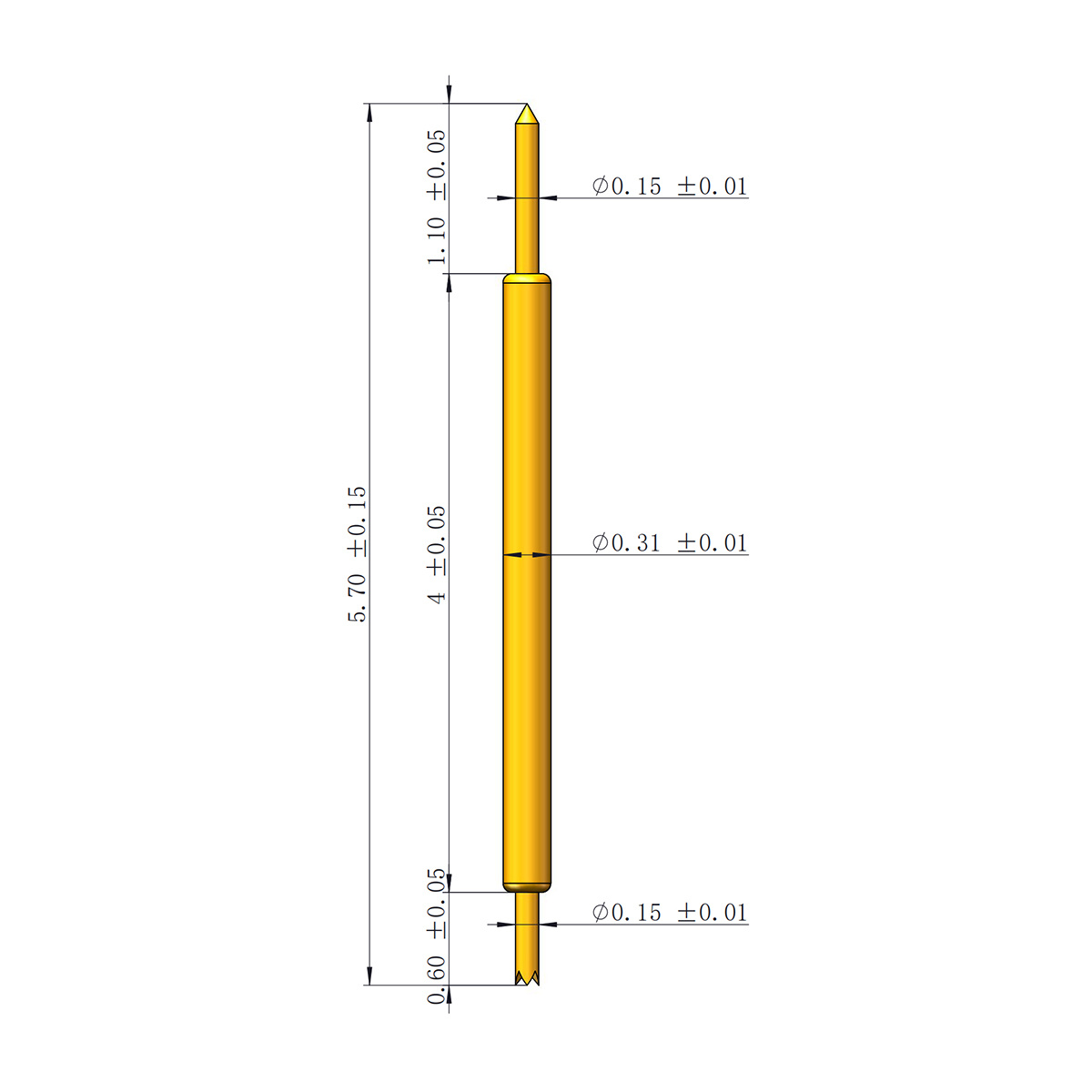

The test probe is a part of the coordinate measuring machine, which is mainly used to contact the workpiece surface, make the mechanical device of the probe shift, generate signals to trigger and collect measurement data. A typical probe consists of a rod and a ruby ball. Depending on the characteristics you want to measure, you can determine the type and size of probe you should use. During the measurement, the stiffness of the probe and the shape of the measuring tip are required to the extent possible. Probe length should be as short as possible. The greater the probe bend or skew, the lower the accuracy. Therefore, try to use a short probe when measuring. There are very few connection points, and each time the probe is connected to the extension rod, additional potential bending and deformation points are introduced. Therefore, you should minimize the number of connections during your application. Make the ball as big as possible? There are two main reasons for this. There is more clearance between the ball and the club, which reduces the chance of being triggered by "jiggle". The larger ball diameter reduces the impact of unpolished surfaces on accuracy. Spring test probes (GKS) usually contain two components. These components must be manufactured to the precision required by microelectronics.

1. Test the probe needle part

Needle mainly plays the role of connection, can be used with a variety of needles. The contact resistance between the test probe and the test point should be as small as possible to ensure the authenticity of the test results. As the needle material, use steel and beryllium copper, respectively hardened, or brass very blunt needle shape.

2. Test the probe needle sleeve part

The sleeve supports the needle and spring. The measurement signal is transmitted to the probe sleeve. To optimize performance, in addition to gilding the needle sleeve, a thin layer of organic protection can be applied to the needle sleeve. The probe pin sleeve (KS) is used to replace the test probe during maintenance of the test fixture. It can be replaced quickly and does not require wiring work. For this purpose, a crimped position is provided on the side. In the meantime, it is important to note that the edge point is not useful until the casing is loaded into the hole. That is, the needle must be inserted into the probe plate before the probe can be loaded.

When measuring with a combination of long probes and long rods, it is not recommended to use the dynamic contact probe of the balance, because using the probe in this case is prone to bending and deformation, which will reduce hardness and lose accuracy. Stainless steel, tungsten carbide, ceramics and various special carbon fiber materials "Renishaw GF". The ruby material is long and hard, and the probe is made with little wear. It also has a very low density, reducing tip mass and preventing the probe from being triggered by machine motion or vibration. Simple ruby probes are more suitable for a variety of detection applications. The rod can be used in a variety of material options, the simple structure of the probe system includes an extremely spherical industrial ruby ball, rod selection. The use of a larger ruby ball can reduce the influence of the surface roughness of the component under test.

Lanyi Electronics - Semiconductor Test Probe Manufacturing Plant

Customer first, quality first, unity and cooperation, mutual benefit and win-win

Copyright © 2022 Dongguan Lanyi Electronic Technology Co., Ltd. All Rights Reserved. 粤ICP备17061266号 Powered by www.300.cn SEO