Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

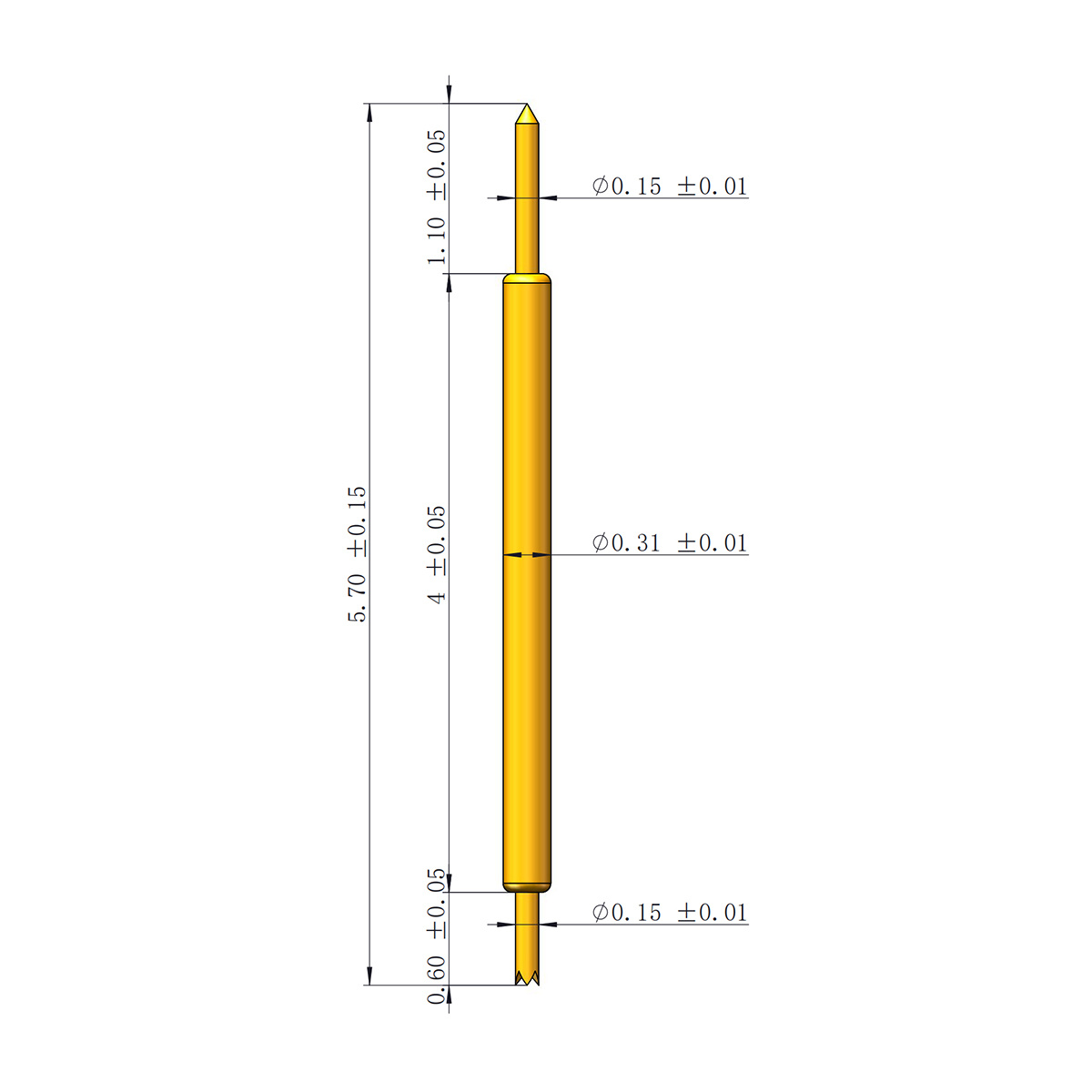

Test the purpose of the probe

Source:

Author:

Test needle is also called test probe in industry. It is divided into spring probe (special probe) and universal probe for PCB test. When the spring probe is used, the test mold should be made according to the wiring condition of the PCB board to be tested. Generally speaking, only one PCB board can be tested per mold. Universal probes in use, only need to have enough points, so now many manufacturers are using universal probes; Spring pins are divided into PCB probe, ICT probe and BGA probe. PCB probe is mainly used for PCB board testing, ICT probe is mainly used for online testing after plugging, BGA probe is mainly used for BGA package testing and chip testing.

1. Phase analysis, composition analysis and inclusion composition identification of metal materials.

2. Identification of gold and silver jewelry, gemstone jewelry, archaeological relics, and criminal investigation.

3. macromolecule, ceramics, concrete, biological, mineral, fiber and other inorganic or organic solid material analysis.

4. the test probe can be used for solid material surface coating, coating analysis, such as: metallized film surface coating detection.

5. Carry out qualitative and quantitative analysis on the micro-components of the material surface, and carry out surface, line and point distribution analysis on the elements of the material surface.

Test the purpose of the probe

1. optical circuit board test probe: circuit board test components before installation only open and short circuit detection probe, most of the domestic probe products can replace imported products;

2. online test probe :PCB circuit board components after the completion of the test probe; The core technology of the product is still in the hands of foreign companies. Some domestic probe products have been developed successfully, which can replace imported probe products.

3. Microelectronic test probe: that is, wafer test or chip IC test probe, the core technology is still in the hands of foreign companies, domestic manufacturers actively participate in the research and development, but only a few manufacturers such as Jingdong Electronics successful production.

4. ICT, commonly known as online tester, is mainly used for assembling circuit board (PCBA) testing. The term "online" here is a literal translation of "in-circuit", which refers primarily to components on the line. On-line testing is a test technique that keeps the circuit open without removing the component pins. "Online" reflects ICT detects assembly problems with the circuit board by testing the short circuit status on the component or wire.

ICT is versatile, accurate in measurement, and has a clear indication of the detected problem. This is a standard test method that makes it easy to deal with problematic PCbas, even for the average electronics tech worker.

ICTTest mainly detects the open and short circuit of PCBA and the welding condition of all components by testing the test points where the probes touch the PCB layout.

Can be divided into open circuit test, short circuit test, resistance test, capacitance test, diode test, transistor test, field effect tube test, IC pin test, etc. Other general and special parts of leakage, misinstallation, parameter value deviation, welding spot welding, circuit board open short circuit and other faults, and through the printer or screen display accurately tell the user which part or open short circuit is located at which point.

Lanyi Electronics - Semiconductor Test Probe Manufacturing Plant

Customer first, quality first, unity and cooperation, mutual benefit and win-win

Copyright © 2022 Dongguan Lanyi Electronic Technology Co., Ltd. All Rights Reserved. 粤ICP备17061266号 Powered by www.300.cn SEO