Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

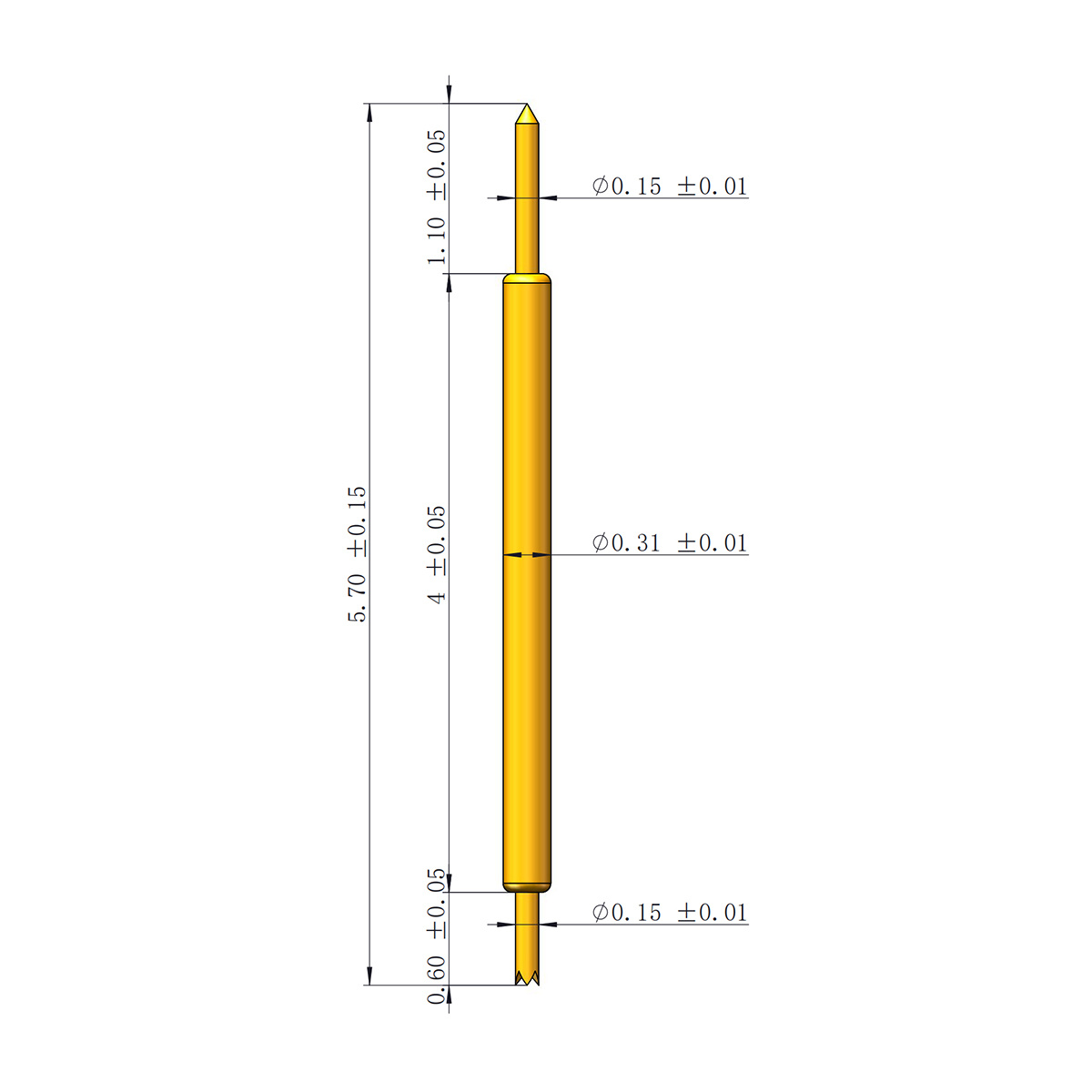

Purpose and type of test probe

Source:

Author:

The probe tests the surface of the gold plated, inside the average life of 30,000 to 100,000 times of high performance springs. At present, the materials used are W and ReW, which are generally elastic, easy to offset, stick to the gold dust, and need to be cleaned several times. Wear and tear needle length, life is average. Next, let's look at the purpose and type of detection probe.

First, the purpose of testing probe testing

The material of no-cleaning needle, this material elasticity is good, in the test is not easy to offset, and non-stick gold dust, no cleaning, so long life. Classification according to use can be divided into:

1. optical circuit board: circuit board detection components before installation only open and short circuit detection, most domestic products can replace imported products;

2. online detection :PCB circuit board components after the installation of the test; The core technology of high-end products is still in the hands of foreign companies. Some domestic products have been developed successfully, which can replace imported products.

3. Microelectronic testing probe: that is, wafer testing or chip IC testing. The core technology is still in the hands of foreign companies, and domestic manufacturers actively participate in research and development, but only a small part of the successful production.

Second, test probe test type

1. Cantilever and vertical.

2. cantilever: blade type.

3. Type of epoxy.

4. vertical: vertical.

5. ICT Series.

The general diameter is 2.54mm-1.27mm, and the industry standard is 100mil, 75mil, 50mil, and the relatively special diameter is only 0.19mm, online circuit detection and functional detection. Also known as ICT detection and FCT detection. It is also a kind of probe widely used at present. Non-standard is generally for a small number of customers who manufacture large testing machines, such as Teradyne and Agilent. Contact points and surfaces of testing machine and testing fixture. The center distance between the two detection points is generally 0.25mm~0.76mm.

A switch has two currents. The wave detects high-frequency signal coaxial, including coaxial with a shielding ring within 10GHz or without a shielding ring within 500MHz. The elasticity of rotating probes is generally not high because they are inherently penetrating and OSPN-processed PCBA tests are common. The diameter of large current ranges from 2.54mm to 4.75mm. Detection current up to 39 amperes.

The diameter of the semiconductor probe is generally 0.50mm-1.27mm. Bandwidth greater than 10GHz,50ω characteristics. Battery and connector contacts are usually optimized for contact, good stability and long life. In addition to the above types, there are temperature and Kelvin, which are rarely used.

It can be divided into open circuit detection, short circuit detection, resistance detection, capacitance detection, diode detection, transistor detection, field effect tube detection, IC pin detection, etc. Other general and special parts of leakage, misinstallation, parameter value deviation, welding spot welding, circuit board open short circuit and other faults, and through the printer or screen display accurately tell the user which part or open short circuit is located at which point.

Lanyi Electronics - Semiconductor Test Probe Manufacturing Plant

Customer first, quality first, unity and cooperation, mutual benefit and win-win

Copyright © 2022 Dongguan Lanyi Electronic Technology Co., Ltd. All Rights Reserved. 粤ICP备17061266号 Powered by www.300.cn SEO