Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

BGA Test Stand: What are the features and prices of the BGA test stand?

Source:

Author:

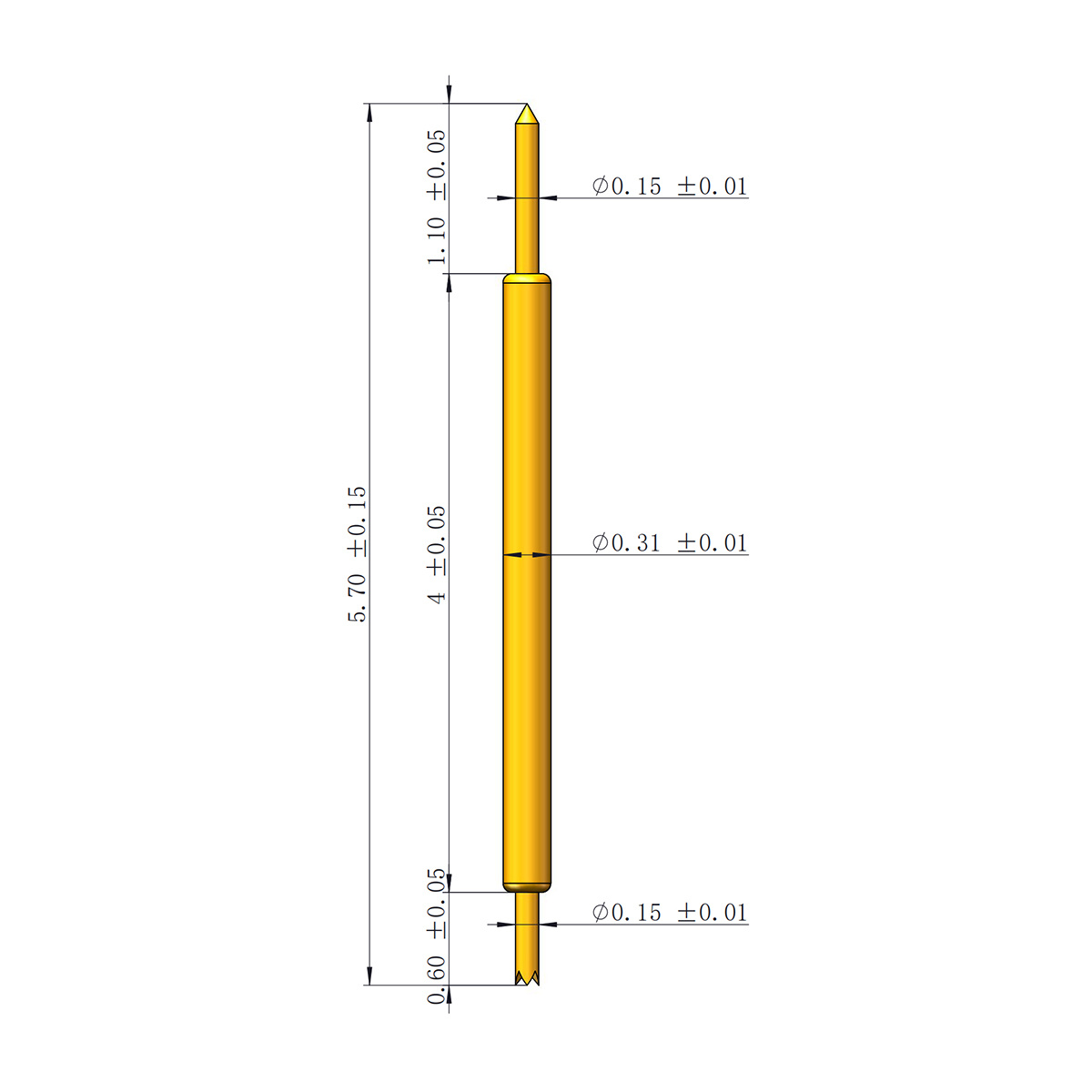

BGA test bench is a fixture for testing BGA encapsulated chips. In addition to the common spot, the BGA test stands on the market are not spot, need to be customized. So BGA test bench: What are the features and prices of BGA test bench? What are the features and prices of the BGA test bed?

1. The imported BGA test stand takes a long time to customize, usually 4-6 weeks. It usually takes about 4 weeks for domestic manufacturers to customize test seats.

2. The price of BGA test platform is generally more expensive, the price is generally several hundred, of course, there are some cheap. The imported test seats are generally more expensive, but the quality is better than the domestic ones. The number of BGA test seats can reach tens of thousands. The number of domestic tests is generally about 10,000.

3. The BGA-encapsulated I/O terminals are distributed in arrays under the package. The advantage of BGA technology over GA technology is that although the number of I/O pins is increased, the spacing of pins is increased rather than reduced, resulting in improved assembly yield; Although the power consumption is increased, the BGA can be welded in a controlled chip breaking mode to improve its electric heating performance. Reduced thickness and weight compared to previous packaging technologies; The parasitic parameter is reduced, the signal transmission delay is small, and the use frequency is greatly increased. It can be assembled by common surface welding, high reliability.

4. Established in 2016, it is a research and development company; Production and sales. The company focuses on research and development; d Customization: chip test socket, aging socket, burning socket, custom socket, Kelvin test socket, precision pin mold.

How to apply BGA test fixture?

At present, in small batch mounting production lines, important main IC chips are directly mounted on the PCBA for functional testing. Once any abnormality is found, it needs to be removed and repaired, which can cause damage to both PCbas and ics, especially CPU chips, which are usually large in number and dense in pins. Chip value is high, easy to damage the chip when disassembling and pasting. Therefore, similar problems can be avoided by using BGA test fixture, as shown in the following figure: The test fixture is set on the PCBA, which can not be directly affixed to the motherboard for functional testing, and directly verify whether the IC meets the requirements. After passing the test, it is pasted on the PCBA, greatly reducing the repair rate. In addition, it is also suitable for QC inspection and motherboard maintenance.

Lanyi Electronics - Semiconductor Test Probe Manufacturing Plant

Customer first, quality first, unity and cooperation, mutual benefit and win-win

Copyright © 2022 Dongguan Lanyi Electronic Technology Co., Ltd. All Rights Reserved. 粤ICP备17061266号 Powered by www.300.cn SEO